Stem stiffness

When purchasing a stem you have not to consider weight as the only performance parameter, a very important characteristic is the RIGIDITY.

Bending

stiffness is defined by moment of inertia (and Young's modulus of the material).

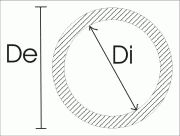

Moment of inertia of a circular hollow section, like a stem (be suspicious

of stems with strange sections) is defined as follows:

|

SECTION

|

AREA

|

MOMENT OF INERTIA

|

|

p(

De^2 - Di^2 )/64

|

p( De^4

- Di^4 )/4

|

Torsional rigidity is defined by polar moment of inertia. It's equal do double of moment of inertia for this type of section. So same considerations are valid.

As formulas shows rigidity modulus increases with fourth power of the diameter. We have a big increase of rigidity with an increase of diameter.

We can do an example: consider 2 stems of equal weigh, one of 30mm diameter(forged stem) and another of 35mm diameter (UltraStem - Roadstem).

|

De

|

Di

|

Area

|

Moment of inertia

|

Flexional stress with 100 Nm torque

|

|

mm

|

mm

|

mm^2

|

mm^4

|

MPa

|

|

30

|

27.64

|

106.8

|

11100

|

135

|

|

35

|

33

|

106.8

|

15500

|

113

|

35mm stem have a stiffness greater than 40%!!

Stresses decreases with third power of diameter, 30mm stem suffer a stress greater than 20%, less safe and life-longer.

So, measure your stem body diameter and compare it with Extralite stems (35mm diameter)

Why don't all manufacturers make UltraStem-type stems?

It's not simple and economic to make this type of stem, extremely rigid, lightweight and safe.

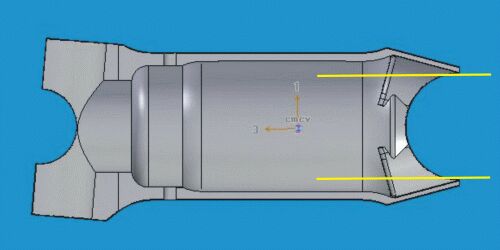

Internal diameter di bigger than stem's mouth and it's not possible to forge it, the only way is a meticulous CNC making.

Yellow lines shows you this limit.

Industrially these tricks are not used for economy and simplicity, deceiving customers with weights and exotic materials.

Besides these considerations there are lots of secrets to avoid stress concentrations, to lighten component and make it safer, we can't explain here these tricks because other brands have often copied our solutions in the past.

![]()

100% made in Italy