25.4mm Handlebar Standard Vs 31.8mm

Wee have practically bench tested standard 25.4mm handlebars/stem combos and found them to be appreciably stiffer than 31.8mm over-sized combos.

This is due to the disadvantages that associate to the inherent wall thickness and the overall dimensioning of 31.8mm handlebars. The phenomena wasn't immediately intuitive - it was experienced by coincidence, then carefully measured and further investigated.

Here follows a brief explanation:

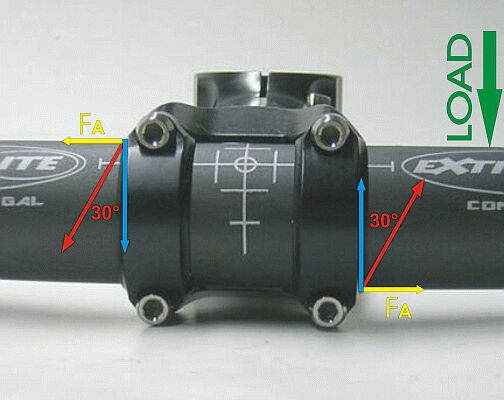

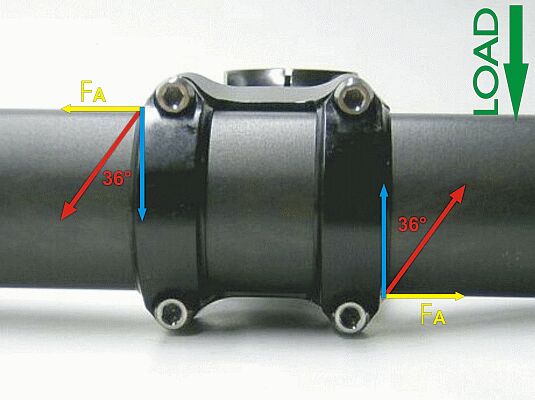

For the same given conditions (this means same bar width, same stem design, same weight, etc) the oversized 31.8mm handlebars generate bigger forces due to the axially-resultant forces. These forces are appreciably lower with the 25.4mm standard.

|

25.4mm

Clamp

|

31.8mm

Clamp

|

|

|

|

FA

is 25% greater on the 31.8mm clamp.

|

|

The 31.8mm stem/bar combo develops higher axial force. This, especially in case of thin/lightweight handlebars, generates small movements at the clamp under load, and thereby a higher flex can be measured at the bar ends.

Geometrically the tube walls of oversize handlebars (for the same-weight) are thinner than the walls of standard handlebar.

Conversely, the central section of an oversized bar requires thicker walls in order to react to the higher clamping forces. This wall thickness gives the 31.8 an inherent dimensioning limitation in terms of how thin they may be made, which is the main reason why 31.8mm handlebars are heavier than 25.4 handlebars.

The bottom line: to achieve the same stiffness of 25.4mm combo you would need an appreciably heavier 31.8m combo.

Additional notes:

Carbon composites perform exceptionally well under tension.

Under impact and compression loads, high strength alloy definitely offers better performance than carbon composite.

Carbon/alloy composite handlebars offer one of the best solutions in terms of safely resisting clamp compression and impact forces while allowing a high level of rigidity.

![]()

100% made in Italy