Absolute performance.

Absolute performance.

Sturdy, precise and incredibly light: no shortcuts to reduce weight.

Weight: 162g.(28h-XD)

Material: special 7075TXX.

Available Drillings: 24h, 28h, 32h.

Frame standards: Thru axle 148mm.

Cassette standards: Sram XD-Drive (11-12s), Shimano 10/M11s or Shimano M12s.

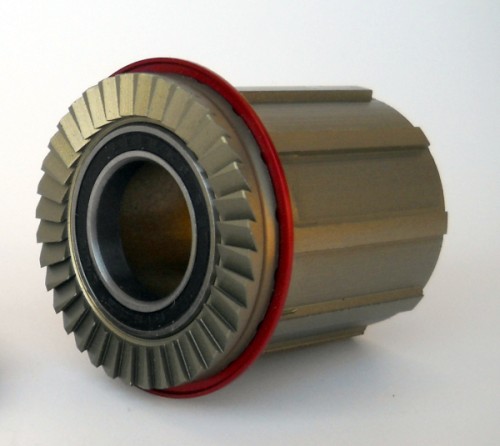

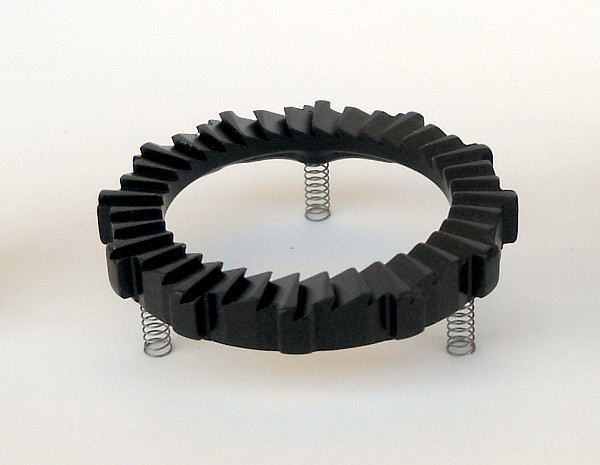

Freewheel: hyper engineered front engagement system, 36-60 points of engagement.

Bearings: 2x17-30 heavy duty + 2x17-26 2RS sealed stainless cartridges.

Axle construction: multi-shaped, 17mm, rectified to micro tolerances.

Micro-Tuner: easy to set external bearing preload system.

Internal sealing: 2xRS soft-touch NBR seals on each bearing.

External sealing: polyurethane Lip seal / Soft-Touch o-ring.

Finishing: "hart coat" sides, black anodized body.

Graphics: laser etched.

Optional: HDC-Hybrid-ceramic bearings.

A new and specifically designed polyurethane lip seal enhances the protection of freewheel mechanism.

The

new "twin-Life" hub-shell features a second additional row of splines

for the floating ring.

The

second fitting position allows to rebuild the hub back to brand new conditions

in case it get badly worn out by a neglected maintenance.

Wheel rotates on 2 heavy duty corrosion resistant stainless bearings (6903-2rs) that can handle 250kg each in the worst static condition.

Straight

pull spokes increase wheel stiffness under sprinting. They appreciably reduce

lateral flex and increase torque transmission reactivity.

All

this with a slight weight reduction too!

Wheel

owners (especially 29ers) will appreciate the extreme spoke camber. Drive spokes

lace closer to right dropout than on any other hub on the market.

This translates into healthier and more rigid wheels.

It

took more than a year of continuous testing to develop and fine tune the HyperRear's

fully-alloy front-engagement freewheel mechanism.

This new device is able to manage extremely high torque values, offers 36-60 quick engagement positions for a precise feel and a minimal friction resistance.

Oversized front engagement freewheel offers a much wider teeth engagement surface upon which to spread the transmission torque.

You can count on beefy and properly-dimensioned bearings coupled with a highly engineered axle, body and parts.

It

is a true racing assembly

which is sensibly

stronger and lighter than conventional pawl systems.

As minor

trade-off its coasting sounds a bit more loud.

And

it handles over a half-ton of chain pull.

Wear and tear of freewheel parts is also higher than conventional pawl systems, however the wearable parts can be easily replaced.

Micro-tuner:

easy to set external bearing preload system integrates external Soft-Touch o-ring

seals.

Precise hub bearing setting ensures low bearing friction, durability and no

play at the rim.

Here you will find pre-calculated spoke lengths, spoke patterns and wheel building tips.

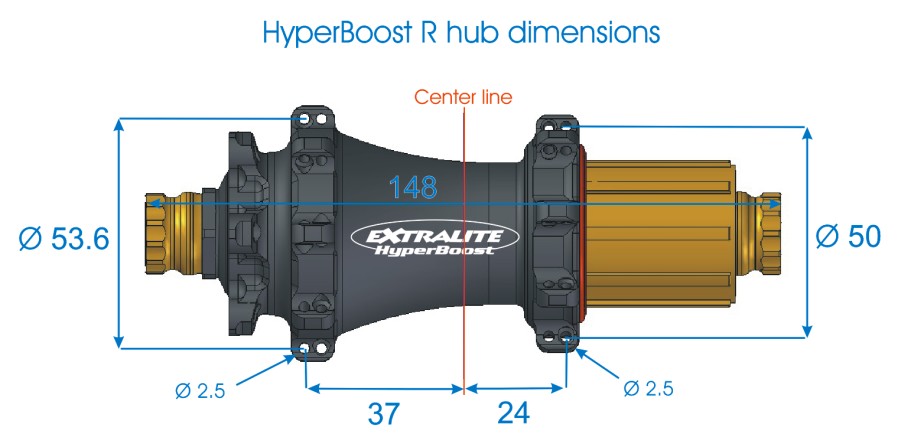

Dimensions

for wheel building

Spoke hole Ø: 2.5mm

Disc flange drilling Ø: 53.6mm

Centre to left flange: 37mm

Centre to right flange: 24mm

Right flange drilling Ø: 50mm

![]()

100% made in Italy