|

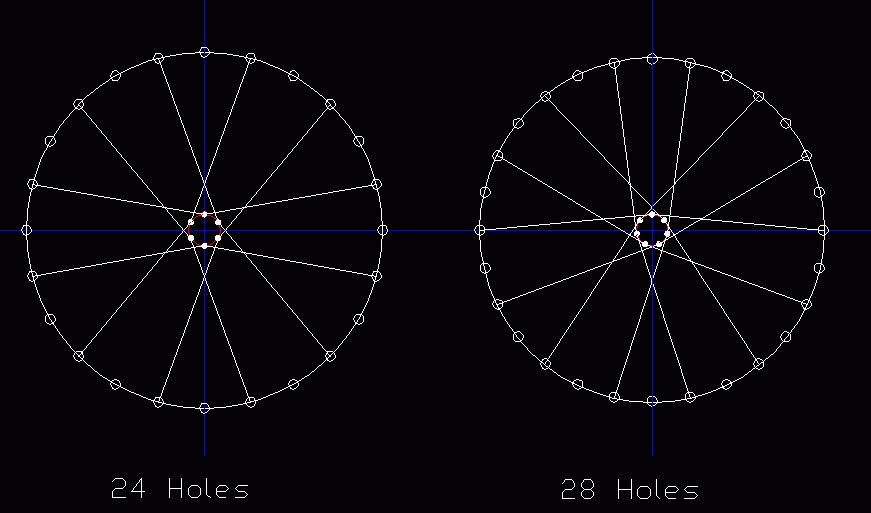

Spoke-end

Diameter |

Spoke

Length

24H |

Spoke

Length

28H |

|

26/27.5/29'

Rims

|

||

|

515

|

252-253

|

258-259

|

|

520

|

255

|

261

|

|

525

|

257-268

|

263-264

|

|

530

|

260

|

266

|

|

535

|

262-263

|

268-269

|

|

540

|

265

|

271

|

|

545

|

267-268

|

273-274

|

|

550 |

270

|

276

|

|

555

|

272-273

|

278-279

|

|

560

|

275

|

281

|

|

565

|

276-277

|

283-284

|

|

570

|

279

|

286

|

|

575

|

281-282

|

288-289

|

|

580

|

285

|

291

|

|

585

|

287-288

|

293

|

|

590

|

290

|

295-296

|

|

595

|

292-293

|

298

|

|

600

|

295

|

300-301

|

|

605

|

297

|

303

|

|

610

|

300

|

305-306

|

|

615

|

301-302

|

308

|

|

620

|

304

|

310-311

|

Table A

We list "spoke-end diameters" every 5mm step. If your "spoke-end diameter" measure is in between 2 steps adjust your spoke length consequently.

3

Important Notes

Rims:

We

consider rims with 2-4mm of offset.

In case of symmetric rims you may add 1mm to front-right and rear-left sides.

Steel

Spokes: Flanges

accept standard spoke heads however we recommend to use only high quality

butted spokes.

Butted spokes are lighter and allow a better spoke

aligningment that translates in a reduced stress of

the parts and an overall stiffer lacing.

Berd

spokes:

Flanges

are designed to fit Berd spokes.

All edges are well rounded thereafter "Tangential

Straightpull Inserts" are not necessary.

Consequently adjust Table A lenghts as follows:

-

subtract 2mm from Table values

if "Without

Tangential Straightpull Inserts"

- keep

values on Table

if "With

Tangential Straightpull Inserts"

Berd Tangential

Straightpull Insert

WARNING: never modify

even slightly the flanges of Extralite

hubs not their surface finish.