E-Bones W F.A.Q/TIPS

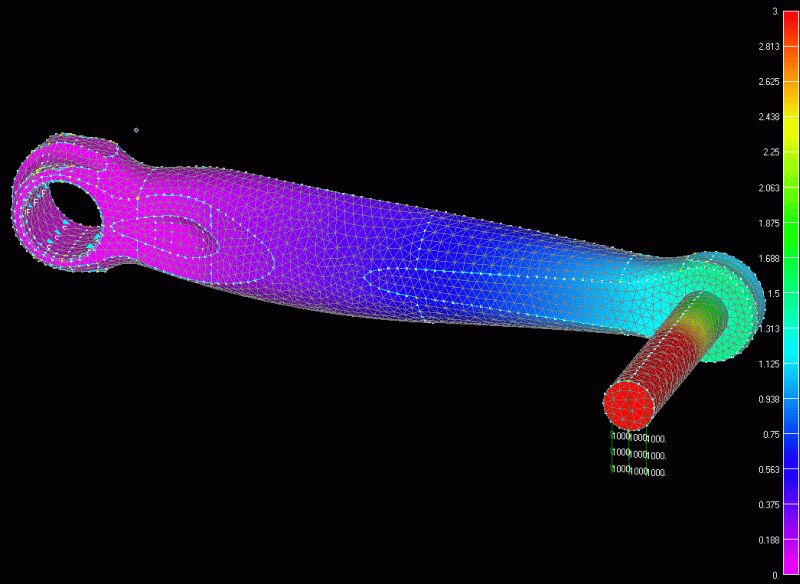

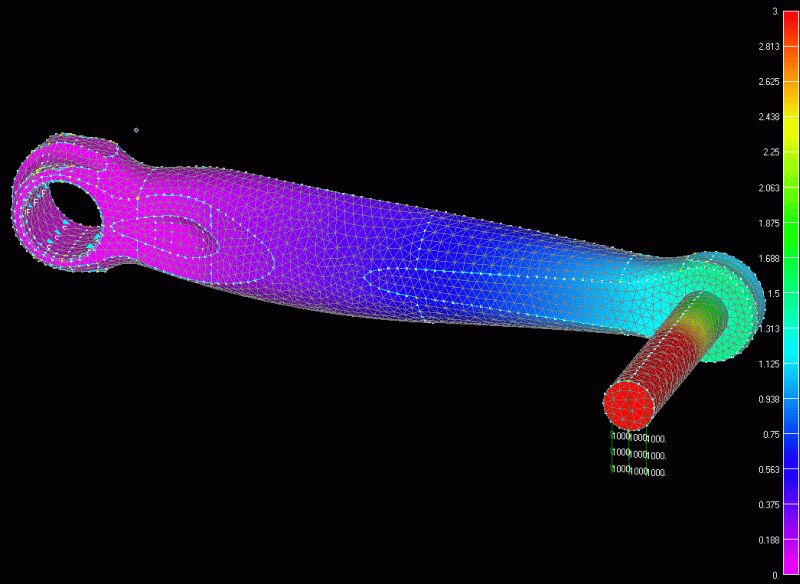

1) What about E-Bones W stiffness?

Deformation is only 1.5mm at pedal eye under 100kg load.

2) Wich E-Bones W version fits my frame ?

Unlike mass-produced crankset E-BonesW are available different BB versions.

Check your BB size, measure it yourself and see table at E-Bones W page.

3) What about E-Bones W models compatibility ?

Compatibility

of E-BonesW BSA68mm & BSA73-68mm.

BSA 68mm version fits BSA68mm shells (with regular derailleur only)

BSA73-68 can fit BSA73mm shells and BSA68mm shells (using 2 included spacers).

BSA 73-68mm version fits also BSA68mm shell + E.type deraillieur (using only

1 included spacer).

Frames equipped with BSA 73mm shell + E.type deraillieur are not compatible

with E-BonesW cranks. Additionally note that in these frames chainline is

way too wide to allow proper shifting performance (unless you use a DH specific

rear hub spaced over 140mm).

Compatibility

of E-BonesW BB30-68, PF30-68 and BB30-73, PF30-73.

E-BonesW BB30-68 version fits BB 30 frame shells (68mm wide) E-BonesW BB30-73

version fits BB 30 frame shells (73mm wide)

E-BonesW PF30-68 version fits PF 30 frame shells (68mm wide) E-BonesW PF30-73

version fits PF 30 frame shells (73mm wide)

Compatibility

of E-BonesW BB91-42.

E-BonesW BB91-42 version fits standard "Press Fit" frame shells (84.5mm wide

/ 68.5mm bearing to bearing, 42mm bearing fitting diam.)

Such as Specialized S-works frames featuring "OS" oversized BB shell.

Compatibility

of E-BonesW with 41mm internal diameter BB.

Unfortunately some bike

manufactures have introduced a weird 41mm bore that has been deliberately

made to force customers to use tipical oem cranksets tipically featuring

smaller axles and smaller 6805 bearings (25-37-7mm).

The weird 41mm bore can't fit the contemporary cranks nor the durable bearings

6806 (30-42-7mm).

In the most cases the frame bb-shell can be re-bored to 42mm but to do this

rather simple operation you'll need a special tool that's not commonly available

yet.

To solve this crazy compatibilily problem we produce a reduced version of

our 6806 bearings that fits the weird 41mm BB shell bore.

To fit this the BB width must be 89.5 to 90mm.

To know your BB shell size check frame manual or ask your frame manufacturer. Otherwise measure it yourself.

4)How do I measure my BB shell ?

To do it put your bike up-side-down and measure your frame bb shell. Measure "left to right bb" shell faces in mm. Just measure distance of frame BB shell "left face" to "right face" , do not iclude your actual bb flanges or parts.

For pressed-in

bearings:

Precisely make the

following measures to get the correct E-BonesW BB standard (pressed-in bearings):

1) BB width (+/- 0.1mm accurancy)

2) Distance between left and right bearing shoulders, if any (+/- 0.1mm accurancy)

3) "Press-Fit" Bearing fitting diameter (+/- 0.02mm accurancy)

5) How do I complete E-Bones W crankset ?

To complete

a 3x9 setup you need OctaRamp 44-32-22E and 2 sets ExtraBolt1

To complete a 2x9 set up you need OctaRamp 44-30T (or OctaRamp Gara) and

1 set ExtraBolt1.2

6) Can

I convert my E-Bones W to fit another BB standard ?

How to convert E-BonesW BSA68mm into BB30-68

(or PF30-68)

E-BonesW BSA68mm can be easily converted into E-BonesW BB30-68 (or PF30-68)

with the following parts:

1set E-BonesW Mounting-ring Euro 10.-

2pc. E-BonesW BB30 (or PF30) bearing cups Euro 19.-/each

E-BonesW BB30-68 (or PF30-68) installation manual

How

to convert E-BonesW BSA73/68mm into BB30-73 (or PF30-73)

E-BonesW BSA73/68mm can be easily converted into E-BonesW BB30-73

(or PF30-73) with

the following parts:

1set E-BonesW Mounting-ring Euro 10.-

2pc. E-BonesW BB30

(or PF30)

bearing cups Euro 19.-/each

E-BonesW BB30-73

(or PF30-73)

installation manual

How to convert

E-BonesW BSA73/BB30-73 into PressFit-41

E-BonesW BSA73mm can be easily converted into E-BonesW PressFit-41 with the

following:

2pcs ABI special "41mm" 6806 bearing Euro 16/each

1set Locking-Oring (to re-execute the axial matching)

E-BonesW PressFit-41 installation manual

Note: E-BonesW BSA68 / BB30-68 / PF30-68 require axle change to be converted

into E-BonesW PressFit-41.

How

to convert E-BonesW BSA68mm into BB91-42

E-BonesW BSA68mm can be easily converted into E-BonesW BB91-42 with the following

parts:

1set E-BonesW Mounting-ring Euro 10.-

2pc. BB91-42 internal spacers Euro 4.-

E-BonesW BB91-42 installation manual

Note: E-BonesW BSA73 / BB30-73 / PF30-73 require

axle change to be converted into E-BonesW BB91-42.

How

to convert E-BonesW BB30-68 into BSA68mm

E-BonesW BB30-68 can be easily converted into E-BonesW BSA68mm with the following

parts:

1pc. E-BonesW BSA68mm "R" bearing cups Euro 19.-

1pc. E-BonesW BSA68mm "L" bearing cups Euro 19.-

E-BonesW BSA68mm installation manual

How

to convert E-BonesW BB30-73 into BSA73/68mm

E-BonesW BB30-73 can be easily converted into E-BonesW BSA73/68mm with the

following parts:

1pc. E-BonesW BSA73/68mm "R" bearing cups Euro 19.-

1pc. E-BonesW BSA73/68mm "L" bearing cups Euro 19.-

1set E-BonesW BSA73/68mm spacers Euro 5.- (optional, to fit BSA68)

E-BonesW BSA73/68mm installation manual

7) My left crank/axle bolt gets loose after riding, what can I do?

Probably

in your case the left crank does not properly press onto the axle hexagon,

it pushes instead on the "bearing-preload and locking OR".

(Warning: This can damage the Axle thin thread and "Bearing Preload"itself)

These conditions can happen only when BB shell is wider than the nominal size

of crank axle version (or when you insert additional spacers or e-type deralier).

As for installation instructions BB shell tolerance should be nominal size

+/- 0.2mm.

To double check it you can try the left crank/axle proper fitting simply taking

out the "Locking Or" and reassembling. This way the crank will not push on

the "Bearing Preload" and will properly press onto the axle fitting. If this

works fine you have found the reason.

In this case change the Locking OR (3x22mm) with a thinner unit (2.5x22mm

or 2x22mm) as quick and symple solution. Please note that we can provide them

if you can't find them locally.

Clean well hexagonal fittings on axle and left crank, assemble as manual instructions,

apply anti-seize grease on fittings and threads, DO NOT use Loctite.

8)

I need to overtight Axle Bolt to get left crank fixed.

1) After several

assembling/disassembling of the "left crank lever" it's necessary to re-execute

the "axial tolerance matching" (you'll need 1 "Locking-O-rin kit").

2a) Never

exceed "axle-bolt" torque also in case the Axle-bolt get loose after riding

(in this case see point 1).

2b) In case the Axle-bolt has already been slightly damaged (at the hex-tool-fitting

only) you can still try the "No Locking O-ring test".

2c) In case the Axle-bolt has already been damaged (at the thread and/or at

the hex-tool-fitting) you'll have to send the crankset to us. Your crank needs

a serious restoration of left crank hex fitting and probably the axle-replacement

too.

Warning: for your safety do not ride the crank in all these cases 2a/2b/2c

.

3) Before replacing "Bearing-preload-ring" check carefully the conditions of the corrispondant thread on the crank axle. If the axle thread is worn out too it will damage the newly replaced "Bearing-preload-ring" very quickly. Then you'll have to send the whole crankset to us for axle-replacing and general servicing.

9) No "Locking O-ring" Test - (for expert mechanic only)

In case your

left crank does not press properly onto the axle hexagon it could push instead

on the "bearing-preload and locking OR".

This can be dangerous for your safety, additionally will damage the Axle thin

thread and "Bearing Preload" itself Warning: do not ride the crank in these

conditions!

These conditions can happen when BB shell is wider than the nominal size (as example BSA68mm should measure 68mm +/- 0.2mm exactly) or when you insert additional spacers, e-type deralier or because the left crank/axle hex fitting has been damaged or worn-out.

To check

if your crankset is still usable but needs to be re-matched try the following

test.

This way the Left crank will have extra room to press-fit onto the axle fitting

and will not push on the "Bearing Preload".

Test procedure:

1) Remove axle-bolt, extract Left-crank lever (use only Isis typoe extractor)

romove "Locking O-ring".

2) Clean well hex fitting (male and feamale), re-insert Left-crank lever,

grease Axle-bolt thread and tighten it at 15Nm (never exceed this value)

3) Carefully use the bike for a test ride only.

4) If this works fine you may have found the reason.

5) In this case replace the original Locking OR with a thinner unit (2x22mm

or 1.8x22mm) ant test again.

(E-BonesW "Locking O-ring kit" is available as spare part) Warning: do not race or ride intensly before repeated tests give repeated positive results.

Alternatively send your Right Crank/axle + Preload Ring + Left Crank to us for a complete servicing.

10) How can I find the correct preload O-ring?

E-BonesW/QRC

preload Locking O-ring are factory matched for a correct axial tolerance of

the crankset.

The factory matching of Locking OR is made selecting one of 3 different thickness

OR sizes to properly match axial tolerances of the crankset.

In

case you have to re-select the correct "Locking OR" for your crankset strictly

follow this procedure:

1) Start installing the thin Locking OR (22x2.0mm)

first precisely following the E-BonesW/QRC installation procedure.

Check it's function: the Preload Ring should have enough stiction to be hardly

turned by hand (normally use the E-BonesW/QRC tuning tool) and still allow

enough room for the left crank press-fitting onto the axle hexagonal-cone.

2)

In case the Preload Ring turns too easily install the medium

Locking OR (22x2.63mm) precisely following the E-BonesW/QRC installation

procedure.

Check it's function: the Preload Ring should have enough stiction to be hardly

turned by hand (normally use the E-BonesW/QRC tuning tool) and still allow

enough room for the left crank press-fitting onto the axle hexagonal-cone.

3)

In case the Preload Ring still turns too easily install the thick

Locking OR (22x3.0mm) precisely following the E-BonesW/QRC installation

procedure.

Check it's function, the Preload Ring should have enough stiction to be hardly

turned by hand (use the E-BonesW/QRC tuning tool) and still allow enough room

for the left crank press-fitting onto the axle hexagonal-cone.

Note: in this case your frame BB shell width is probably below its nominal

dimensional tolerance.

The "locking O-ring kit" is available as spare part and includes includes 22x 2.0mm / 2.63mm / 3.0mm O-rings.

The function of Locking O-ring is to add stiction to Preload Ring and avoid unwanted turning while riding.

Too

much compression does not allow the proper fitting of the Left crank onto

the hexagonal axle, very dangerous, warning!

If the Locking O-ring does not get the right amount of compression it does

not lock the "bearing preload ring"properly.

You

may need a thinner Locking O-ring to compensate a slightly wider (+0.2/+0.4mm)

frame shell.

You may need a thicker Locking O-ring to compensate a slightly undersized

(-0.2/-0.4mm) frame shell.

11) My crank make strange noises, what can I do?

Noises can

come from bolt-on parts only, to eliminate them check well the following:

1) Left crank / axle tightening (try the procedure described above)

2) BB bearing cups/frame tightening, (additionally you can secure them with

Loctite 243).

3) Chainring bolts tightening (especially check theit complete threading in

on OcaRamp 30T)